Pfupiso: Nheyo yekubatanidza, kupatsanura, kugadzira, maitiro uye zvishandiso zvezvinhu zvinodzivirira silane zvewaya netambo zvinotsanangurwa muchidimbu, uye mamwe maitiro ezvinhu zvinodzivirira silane zve polyethylene zvakabatana zvakasikwa mukushandiswa uye kushandiswa pamwe nezvinhu zvinokanganisa mamiriro ekubatanidza zvinhu zvinounzwa.

Mashoko akakosha: Silane cross-linking; Natural cross-linking; Polyethylene; Insulation; Waya netambo

Nyaya dzesimbi dzepolyethylene dzakasanganiswa neSilane dzava kushandiswa zvakanyanya muindasitiri yewaya netambo senzira yekudzivirira tambo dzemagetsi dzine voltage shoma. Zvinhu zviri mukugadzirwa kwewaya netambo dzine cross-linked, uye peroxide cross-linking uye irradiation cross-link zvichienzaniswa nemidziyo yekugadzira inodiwa zviri nyore, zviri nyore kushandisa, mutengo wakaderera uye zvimwe zvakanakira, zvave chinhu chinotungamira pakushandisa waya dzine voltage shoma dzine insulation.

1.Silane cross-linked cable material cross-link musimboti

Kune maitiro maviri makuru anobatanidzwa mukugadzira silane cross-linked polyethylene: grafting uye cross-linking. Mukuita grafting, polymer inorasikirwa neH-atomu yayo pa tertiary carbon atom pasi pesimba re free initiator uye pyrolysis kuita free radicals, iyo inopindura ne – CH = CH2 group yevinyl silane kugadzira polymer yakaganhurirwa ine trioxysilyl ester group. Mukuita cross-linking, graft polymer inotanga yaiswa hydrolyzed mumvura kuti igadzire silanol, uye – OH inosangana neboka reSi-OH riri pedyo kuti igadzire Si-O-Si bond, nokudaro ichibatanidza macromolecule epolymer.

2. Silane cross-linked cable zvinhu uye nzira yayo yekugadzira cable

Sezvamunoziva, kune nzira dzekugadzira tambo dzakabatana nesimbi dzine nhanho mbiri nenhanho imwe chete dzesilane netambo dzadzo. Musiyano uripo pakati penzira yematanho maviri nenzira yenhanho imwe chete uri pakuti nzira yekubatanidza silane inoitwa sei, nzira yekubatanidza pamudziri wezvinhu zvetambo yenzira yematanho maviri, nzira yekubatanidza mufekitori yekugadzira tambo yenzira yenhanho imwe. Zvinhu zvekudzivirira silane zvine nhanho mbiri zvine mugove mukuru wemusika zvinoumbwa nezvinhu zvinonzi A neB, neA iri polyethylene yakasanganiswa nesimbi ine silane nesimbi ine B iri catalyst master batch. Chinhu chinodzivirira chinobva chabatanidzwa mumvura inodziya kana muutsi.

Kune rumwe rudzi rwechinodzivirira polyethylene chine matanho maviri, apo chinhu cheA chinogadzirwa nenzira yakasiyana, nekuisa vinyl silane zvakananga mu polyethylene panguva yekugadzira kuti polyethylene iwane cheni dzine matavi e silane.

Nzira yedanho rimwe chete inewo mhando mbiri, nzira yechinyakare yedanho rimwe chete ndeyekusanganisa zvinhu zvakasiyana-siyana zvichienderana nefomula muhuwandu hwesystem yekuyera chaiyo, kuita extruder yakakosha yakagadzirirwa zvakananga mudanho rimwe chete kuti ipedzise grafting uye extrusion ye wire insulation core, mukuita uku, hapana granulation, hapana chikonzero chekuti wire material itore chikamu, nefekitori ye cable kuti ipedze yega. Iyi michina yekugadzira tambo ine silane cross-linked uye tekinoroji yekugadzira inotorwa kubva kunze kwenyika uye inodhura.

Rumwe rudzi rwezvinhu zvinodzivirira tambo zvine cross-linked polyethylene zvinogadzirwa nevagadziri vezvinhu zvinodzivirira tambo, zvese zviri muchimiro chemhando yepamusoro zvichienderana nechikamu chenzira yakakosha yekusanganisa, kurongedza nekutengeswa, hapana zvinhu zveA neB, tambo inogona kuiswa zvakananga mu extruder kuti ipedze danho panguva imwe chete nekubatanidza uye kubvisa tambo dzinodzivirira tambo. Chinhu chakasiyana chenzira iyi ndechekuti hapana chikonzero che extruders dzinodhura, sezvo maitiro ekubatanidza silane anogona kupedzwa mu PVC extruder yakajairika, uye nzira yematanho maviri inobvisa kudiwa kwekusanganisa zvinhu zveA neB zvisati zvaburitswa.

3. Kuumbwa kwemusanganiswa

Kuumbwa kwesimbi ye polyethylene yakabatana ne silane kunowanzo kuve ne resin, initiator, silane, antioxidant, polymerization inhibitor, catalyst, nezvimwewo.

(1) Resin yebase inowanzova resin yepolyethylene yakaderera (LDPE) ine melt index (MI) ye2, asi munguva pfupi yapfuura, nekuvandudzwa kwetekinoroji ye synthetic resin uye kumanikidzwa kwemitengo, linear low density polyethylene (LLDPE) yakashandiswawo kana kushandiswa zvishoma se base resin yezvinhu izvi. Ma resin akasiyana anowanzova nemhedzisiro yakakura pakubatanidza uye kubatanidza nekuda kwekusiyana kwemukati macromolecular structure yawo, saka fomura yacho ichachinjwa nekushandisa ma base resin akasiyana kana rudzi rumwe rwe resin kubva kuvagadziri vakasiyana.

(2) Chinhu chinowanzo shandiswa i diisopropyl peroxide (DCP), chinhu chikuru ndechekunzwisisa huwandu hwedambudziko, zvishoma zvekukonzera silane grafting hazvina kukwana; zvakanyanya zvekukonzera polyethylene cross-linking, izvo zvinoderedza kuyerera kwayo, pamusoro pe extruded insulation core yakaoma, yakaoma kudzvanya system. Sezvo huwandu hweinotanga hushoma uye hunonzwa, zvakakosha kuti uiparadzire zvakaenzana, saka inowanzo wedzerwa pamwe chete ne silane.

(3) Silane inowanzo shandiswa vinyl unsaturated silane, kusanganisira vinyl trimethoxysilane (A2171) uye vinyl triethoxysilane (A2151), nekuda kwekukurumidza kwehydrolysis rate yeA2171, saka sarudza vanhu vakawanda veA2171. Saizvozvowo, pane dambudziko rekuwedzera silane, vagadziri vemidziyo yetambo vari kuedza kuwana muganho wayo wakaderera wekuderedza mitengo, nekuti silane inotengeswa kunze kwenyika, mutengo wacho unodhura.

(4) Anti-oxidant ndeyekuona kuti kugadziriswa kwepolyethylene kwakasimba uye tambo dzinodzivirira kukwegura uye dzakawedzerwa, anti-oxidant mukugadzirwa kwe silane ine basa rekudzivisa reaction yekubatanidza, saka maitiro ekubatanidza, kuwedzera kwe anti-oxidant kunofanira kungwarira, huwandu hwakawedzerwa hunofanirwa kutariswa nehuwandu hweDCP kuti huenderane nesarudzo. Mukuita kwekubatanidza kwematanho maviri, antioxidant yakawanda inogona kuwedzerwa mu catalyst master batch, izvo zvinogona kuderedza kukanganisa pakugadzirwa kwekubatanidza. Mukuita kwekubatanidza kwematanho rimwe chete, antioxidant iripo mukugadzirwa kwese kwekubatanidza, saka kusarudza mhando nehuwandu kwakakosha. Ma antioxidants anowanzoshandiswa ndeaya 1010, 168, 330, nezvimwewo.

(5) Mushonga wepolymerization unowedzerwa kuitira kudzivirira mamwe ma "grafting" uye maitiro e "cross-linking" e "side reactions" anoitika, mu "grafting" kuwedzera mushonga we "anti-cross-linking", unogona kuderedza kuitika kwe "C2C cross-linking", nokudaro uchivandudza processing fluidity, uyezve, kuwedzerwa kwe "graft" mumamiriro akafanana kuchatungamirwa ne "hydrolysis" ye "silane" pa "polymerization inhibitor" kunogona kuderedza hydrolysis ye "grafted polyethylene", kuvandudza kugadzikana kwenguva refu kwe "graft material".

(6) MaCatalyst anowanzo kuve ma organotin derivatives (kunze kwe natural crosslinking), anonyanya kuzivikanwa ari dibutyltin dilaurate (DBDTL), iyo inowanzo wedzerwa muchimiro chemasterbatch. Mukuita kwematanho maviri, graft (A material) ne catalyst master batch (B material) zvinoiswa zvakasiyana uye zvinhu zveA neB zvinosanganiswa pamwe chete zvisati zvawedzerwa kune extruder kudzivirira pre-crosslinking yechinhu cheA. Panyaya ye one-step silane cross-linked polyethylene insulations, polyethylene iri mupakeji haisati yaiswa, saka hapana dambudziko pre-cross-linking uye saka catalyst haifanirwe kuiswa zvakasiyana.

Pamusoro pezvo, kune ma silane akabatanidzwa aripo pamusika, ayo ari musanganiswa we silane, initiator, antioxidant, mamwe mafuta uye anti-copper agents, uye anowanzo shandiswa munzira dzekubatanidza silane muzvikamu zve cable.

Saka, kugadzirwa kwe silane cross-linked polyethylene insulation, iyo musanganiswa wayo usingaonekwe sewakaoma uye unowanikwa muruzivo rwakakodzera, asi maformula akakodzera ekugadzira, anoenderana nekugadziriswa kuti apedziswe, izvo zvinoda kunzwisisa kwakazara kwebasa rezvikamu mukugadzirwa uye mutemo wemhedzisiro yazvo pakushanda uye simba razvo.

Mumhando dzakasiyana-siyana dzezvinhu zvetambo, zvinhu zvetambo zvine silane cross-linked cable (zvingave nhanho mbiri kana nhanho imwe chete) zvinoonekwa semhando chete yemakemikari anoitika mukuburitsa, mamwe marudzi akadai se polyvinyl chloride (PVC) cable material uye polyethylene (PE) cable material, extrusion granulation process inzira yekusanganisa physical, kunyangwe kana makemikari achibatanidza uye achivhenekesa cross-linking cable material, kungave mu extrusion granulation process, kana extrusion system Cable, hapana maitiro emakemikari anoitika, saka, mukuenzanisa, kugadzirwa kwezvinhu zvetambo zvine silane cross-linked uye cable insulation extrusion, process control inonyanya kukosha.

4. Maitiro ekugadzira silane ine cross-linked polyethylene insulation ine nhanho mbiri

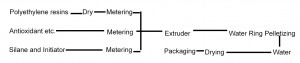

Maitiro ekugadzira chinhu chepurasitiki chinoputira silane chine nhanho mbiri chinogona kuratidzwa muchidimbu neMufananidzo 1.

Mufananidzo 1 Maitiro ekugadzira zvinhu zviviri zvinodzivirira silane cross-linked polyethylene A

Zvimwe zvinhu zvakakosha mukugadzirwa kwepurasitiki ine silane cross-linked polyethylene insulation ine nhanho mbiri:

(1) Kuomesa. Sezvo polyethylene resin ine mvura shoma, kana ikaburitswa pakupisa kwakanyanya, mvura inokurumidza kusangana nemapoka esilyl kuti igadzire cross-linking, izvo zvinoderedza kuyerera kwekunyunguduka uye zvinogadzira pre-cross-linking. Chinhu chapedzwa chine mvura mushure mekutonhorera kwemvura, izvo zvinogonawo kukonzera pre-crosslinking kana isina kubviswa, uye inofanirawo kuomeswa. Kuti ive nechokwadi chekuti kuomesa kwakanaka, unit yekuomesa yakadzika inoshandiswa.

(2) Kuyera. Sezvo kururama kwekugadzirwa kwezvinhu kwakakosha, chikero chekuyera uremu chinopinzwa kunze kwenyika chinowanzo shandiswa. Resin yepolyethylene uye antioxidant zvinoyerwa uye zvinopihwa kuburikidza nechiteshi chekudyisa cheextruder, nepo silane neinitiator zvichipinzwa nepombi yemvura mubhare rechipiri kana rechitatu reextruder.

(3) Kubatanidza zvinhu kubva mugomba. Maitiro ekubatanidza zvinhu kubva mugomba resilane anopedzwa mugomba reextruder. Maitiro ekugadzirisa zvinhu kubva mugomba reextruder, kusanganisira tembiricha, kusanganiswa kwezvikururu, kumhanya kwezvikururu uye mwero wekudya, zvinofanirwa kutevedzera musimboti wekuti zvinhu zviri muchikamu chekutanga chegomba reextruder zvinogona kunyungudutswa zvizere uye kusanganiswa zvakaenzana, kana peroxide ikasaparara nguva isati yakwana, uye kuti zvinhu zvakafanana zvakakwana muchikamu chechipiri chegomba reextruder zvinofanira kuoreswa zvizere uye maitiro ekubatanidza apedzwa. Kupisa kwechikamu cheextruder chakajairika (LDPE) kunoratidzwa muTafura 1.

Tafura 1 Tembiricha yenzvimbo dze extruder dzine matanho maviri

| Nzvimbo yekushandira | Nzvimbo 1 | Nzvimbo yechipiri | Nzvimbo 3 ① | Nzvimbo 4 | Nzvimbo 5 |

| Tembiricha P °C | 140 | 145 | 120 | 160 | 170 |

| Nzvimbo yekushandira | Nzvimbo 6 | Nzvimbo 7 | Nzvimbo 8 | Nzvimbo 9 | Muromo unofa |

| Tembiricha °C | 180 | 190 | 195 | 205 | 195 |

①ndipo panowedzerwa silane.

Kumhanya kweskuruu yeextruder kunosarudza nguva yekugara uye mhedzisiro yekusanganisa kwezvinhu zviri muextruder, kana nguva yekugara iri pfupi, kuora kweperoxide hakuna kukwana; kana nguva yekugara iri yakareba zvakanyanya, viscosity yezvinhu zvakaburitswa inowedzera. Kazhinji, avhareji yenguva yekugara yegranule muextruder inofanira kudzorwa mukutanga kuora kwehafu yenguva ye5-10. Kumhanya kwekudya hakungogumiri pakukanganisa nguva yekugara kwezvinhu, asiwo pakusanganisa nekuchekwa kwezvinhu, kusarudza kumhanya kwakakodzera kwekudya kwakakoshawo zvikuru.

(4) Kurongedza. Zvinhu zvinodzivirira silane zvine matanho maviri zvinofanirwa kurongedzwa mumabhegi epurasitiki nealuminium mumhepo yakananga kuti hunyoro husapfuure.

5. Maitiro ekugadzira zvinhu zvinodzivirira silane yakabatana ne polyethylene ine nhanho imwe chete

Zvinhu zvinodzivirira simbi zvine nhanho imwe chete (single-linked polyethylene insulation material) nekuda kwekuita kwayo grafting zviri mu cable factory extrusion ye wire insulation core, saka wire insulation extrusion extrusion tembiricha yakakwira zvakanyanya kupfuura two-step method. Kunyangwe fomura ye single-step silane cross-linked polyethylene insulation yakafungwa zvizere mukupararira nekukurumidza kwe initiator uye silane uye material shear, asi grafting process inofanira kuvimbiswa netembiricha, inova one-step silane cross-linked polyethylene insulation production production plant yakasimbisa kakawanda kukosha kwesarudzo chaiyo ye extrusion tembiricha, tembiricha inokurudzirwa ye extrusion inoratidzwa muTafura 2.

Tafura 2 Tembiricha yekunze kwenzvimbo imwe neimwe ine nhanho imwe chete (chikamu: ℃)

| Nzvimbo | Nzvimbo 1 | Nzvimbo yechipiri | Nzvimbo 3 | Nzvimbo 4 | Flange | Musoro |

| Tembiricha | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

Uku ndiko kumwe kusasimba kwemaitiro e polyethylene ine nhanho imwe chete ye silane cross-linked, iyo isingawanzodiwi pakuburitsa tambo mumatanho maviri.

6. Midziyo yekugadzira

Midziyo yekugadzira ivimbiso yakakosha yekudzora mashandiro. Kugadzirwa kwetambo dzakabatana ne silane kunoda mwero wepamusoro wekudzora mashandiro, saka kusarudza michina yekugadzira kwakakosha zvikuru.

Kugadzirwa kwepurasitiki ine silane ine cross-linked polyethylene insulation material ine nhanho mbiri. Midziyo yekugadzira zvinhu, iyo parizvino iri yemukati ine isotropic parallel twin-screw extruder ine huremu husingadhuri, zvishandiso zvakadaro zvinogona kusangana nezvinodiwa zvekutonga kwakarurama, kusarudza kureba uye dhayamita ye extruder ine twin-screw extruder kuti ive nechokwadi chekuti nguva yekugara kwezvinhu, sarudzo yehuremu husingadhuri hunotengeswa kunze kwenyika kuti ive nechokwadi chekuti zvinhu zvacho zvakarurama. Ehe, kune zvakawanda zvinodiwa zvemidziyo zvinoda kutariswa zvizere.

Sezvambotaurwa, michina yekugadzira tambo ine nhanho imwe chete ye silane cross-linked mufekitori yetambo inotengeswa kunze kwenyika, inodhura, vagadziri vemidziyo yemumba havana michina yekugadzira yakafanana, chikonzero ndechekushaikwa kwekushandira pamwe pakati pevagadziri vemidziyo nevaongorori vemafomura nemaitiro.

7. Silane yepurasitiki inoputirwa nepurasitiki yechisikigo

Zvinhu zvinodzivirira silane natural cross-linked polyethylene zvakagadzirwa mumakore achangopfuura zvinogona kusanganiswa mumamiriro ekunze mukati memazuva mashoma, pasina kunyudzwa mumvura inodziya kana utsi. Zvichienzaniswa nenzira yechinyakare yekubatanidza silane, zvinhu izvi zvinogona kuderedza maitiro ekugadzira kune vagadziri vetambo, zvichideredza mari yekugadzira uye kuwedzera kushanda zvakanaka kwekugadzira. Silane natural cross-linked polyethylene insulation iri kuzivikanwa uye kushandiswa nevagadziri vetambo.

Mumakore achangopfuura, silane natural cross-linked polyethylene insulation yemumba yakura uye yakagadzirwa yakawanda, ine zvimwe zvakanakira mumutengo zvichienzaniswa nezvinhu zvinotengeswa kunze kwenyika.

7. 1 Mazano ekugadzira silane naturally cross-linked polyethylene insulation

Silane natural cross-linked polyethylene insulation inogadzirwa nenzira ine matanho maviri, ine fomura imwechete inosanganisira base resin, initiator, silane, antioxidant, polymerisation inhibitor uye catalyst. Kugadzirwa kwe silane natural cross-linked polyethylene insulators kwakavakirwa pakuwedzera silane grafting rate yeA material uye kusarudza catalyst inoshanda zviri nani pane silane water warm-linked polyethylene insulators. Kushandiswa kwezvinhu zveA zvine silane grafting rate yakakwira pamwe chete necatalyst inoshanda zviri nani kuchaita kuti silane cross-linked polyethylene insulator ikwanise cross-link nekukurumidza kunyangwe patembiricha yakaderera uye pasina hunyoro hwakakwana.

Zvinhu zveA zve silane naturally cross-linked polyethylene insulators zvinogadzirwa ne copolymerisation, uko huwandu hwe silane hunogona kudzorwa padanho repamusoro, nepo kugadzirwa kwezvinhu zveA zvine mwero wepamusoro we grafting ne grafting silane kwakaoma. Base resin, initiator uye silane zvinoshandiswa muresipi zvinofanirwa kuchinjwa uye kugadziriswa maererano nekusiyana uye kuwedzera.

Kusarudzwa kwe resist uye kugadziriswa kwemuyero wayo kwakakoshawo, sezvo kuwedzera kwehuwandu hwekuiswa kwe silane kunotungamira kune akawanda maitiro eCC crosslinking side. Kuti kuvandudzwa kwe processing fluidity uye mamiriro epamusoro pechinhu cheA che extrusion inotevera ye cable, huwandu hwakakodzera hwe polymerization inhibitor hunodiwa kuti hudzivirire zvinobudirira CC crosslinking uye pre-crosslinking.

Pamusoro pezvo, macatalyst anoita basa rakakosha mukuwedzera mwero wekubatanidza uye anofanira kusarudzwa semacatalyst anoshanda zvakanaka ane zvinhu zvisina simbi zvinoshanduka.

7. 2 Nguva yekubatanidza silane ne polyethylene insulation yakabatana zvakasikwa

Nguva inodiwa kuti upedze kusanganisa silane natural cross-linked polyethylene insulation mumamiriro ayo echisikigo zvinoenderana nekupisa, hunyoro uye ukobvu hweinsulation layer. Kana tembiricha nehunyoro zvakakwirira, ukobvu hweinsulation layer hutete, nguva yekubatanidza ipfupi inodiwa, uye nguva yakareba zvakasiyana. Sezvo tembiricha nehunyoro zvichisiyana kubva munzvimbo nenzvimbo uye kubva mumwaka kusvika mwaka, kunyangwe munzvimbo imwe chete uye panguva imwe chete, tembiricha nehunyoro nhasi nemangwana zvichave zvakasiyana. Saka, panguva yekushandiswa kwezvinhu, mushandisi anofanira kusarudza nguva yekubatanidza zvichienderana netembiricha nehunyoro hwenzvimbo uye huripo, pamwe chete netsanangudzo yetambo nehunyoro hweinsulation layer.

Nguva yekutumira: Nyamavhuvhu-13-2022