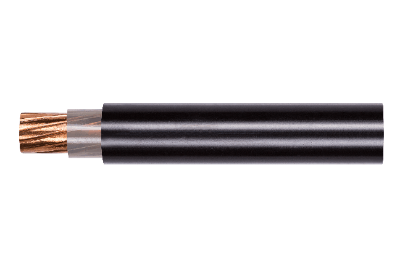

Polyethylene (PE) inoshandiswa zvakanyanya mukuputira nekuvhara tambo dzemagetsi netambo dzekutaurirananekuda kwesimba rayo rakanaka kwazvo remakanika, kusimba kwayo, kuramba kupisa, kudzikamisa kupisa, uye kugadzikana kwemakemikari. Zvisinei, nekuda kwehunhu hwePE pachayo, kuramba kwayo kukanganiswa nekukanganiswa kwezvakatipoteredza kwakaderera. Dambudziko iri rinonyanya kuoneka kana PE ikashandiswa sechikamu chekunze chetambo dzakakura dzakadzivirirwa.

1. Maitiro ePE Sheath Cracking

Kutsemuka kwe PE sheath kunowanzoitika mumamiriro maviri:

a. Kutsemuka Kwepfungwa Dzinokonzerwa Nezvakatipoteredza: Izvi zvinoreva chiitiko apo sheath inotsemuka kubva pamusoro nekuda kwekushushikana kwakabatana kana kusangana nezvinhu zvezvakatipoteredza mushure mekuiswa kwetambo nekushanda. Izvi zvinonyanya kukonzerwa nekushushikana kwemukati mukati mesheath uye kugara kwenguva refu uchisangana nezvinwiwa zvepolar. Tsvagiridzo yakakura pamusoro pekugadzirisa zvinhu yakagadzirisa zvakanyanya rudzi urwu rwekutsemuka.

b. Kutsemuka Kwesimba Remagetsi: Izvi zvinoitika nekuda kwekusakwana kwechimiro mutambo kana maitiro asina kukodzera ekubvisa sheath, zvichikonzera kushushikana kwakanyanya uye kutsemuka kunokonzerwa nekuchinja kwesimba panguva yekuisa tambo. Rudzi urwu rwekutsemuka runonyanya kuoneka mumatanda ekunze etambo dzakagadzirwa nesimbi dzakakura.

2. Zvinokonzera Kutsemuka kwePeath uye Matanho Ekuvandudza

2.1 Kupesvedzera kweCableTepi yeSimbiMaumbirwo

Mumatambo ane dhayamita huru yekunze, dhayamita yakadzivirirwa inowanzo gadzirwa ne tape wraps dzesimbi dzine mativi maviri. Zvichienderana nedhayamita yekunze yetambo, ukobvu hwe tape yesimbi hunosiyana (0.2mm, 0.5mm, uye 0.8mm). Matepi esimbi akakora ane tambo dzakasimba uye haana kusimba zvakanyanya, zvichikonzera nzvimbo yakakura pakati pe matanda epamusoro neapasi. Panguva yekubuda, izvi zvinokonzera mutsauko mukuru muukobvu hwe sheath pakati pe matanda epamusoro neapasi e danda rakadzivirirwa. Nzvimbo dzakatetepa dze sheath dziri kumucheto kwe tape yesimbi yekunze dzinosangana nekumanikidzwa kukuru uye ndidzo nzvimbo huru dzinozotsemuka mune ramangwana.

Kuti kuderedze kukanganiswa kwetepi yesimbi yakashongedzwa padanda rekunze, danda rekudzivirira rine ukobvu hwakati rinoputirwa kana kuburitswa pakati petepi yesimbi nedanda rePE. danda iri rekudzivirira rinofanira kunge rakakora zvakaenzana, risina makwinya kana kubuda. Kuwedzerwa kwedanda rekudzivirira kunovandudza kutsetseka pakati pezvikamu zviviri zvetepi yesimbi, kunoita kuti danda rePE rive rakafanana, uye, pamwe chete nekukotama kwedanda rePE, kunoderedza kushushikana kwemukati.

ONEWORLD inopa vashandisi ukobvu hwakasiyana hwezvinhu zvakadzivirirwa nesimbi zvakaputirwa netepi yesimbikusangana nezvinodiwa zvakasiyana-siyana.

2.2 Mhedzisiro yeMaitiro Ekugadzira Cable

Matambudziko makuru ekubvisa tambo dzekunze dzakagadzirwa nedhayamita yakakura ndeyekutonhodza kusina kukwana, kugadzirira kwakashata kwemould, uye kutambanudza kwakawandisa, zvichikonzera kushushikana kwakanyanya mukati meganda. Tambo hombe, nekuda kweganda radzo gobvu uye rakafara, dzinowanzo sangana nemiganhu muhurefu nehuwandu hwematangi emvura pamitsetse yekugadzira tambo. Kutonhodza kubva pamusoro pe200 degrees Celsius panguva yekubvisa tambo kusvika patembiricha yemukamuri kunounza matambudziko. Kutonhodza kusina kukwana kunotungamira kune ganda rakapfava pedyo neganda rezvombo, zvichikonzera kukwenya pamusoro peganda kana tambo yakamonerwa, zvichizoguma nekutsemuka nekutyoka panguva yekuisa tambo nekuda kwesimba rekunze. Uyezve, kutonhora kusina kukwana kunobatsira kuwedzera simba remukati mushure mekumonerwa, zvichiwedzera njodzi yekutsemuka kweganda pasi pesimba guru rekunze. Kuti uve nechokwadi chekutonhodza kwakakwana, kuwedzera hurefu kana huwandu hwematangi emvura kunokurudzirwa. Kuderedza kumhanya kwekubvisa tambo uku uchichengetedza purasitiki yakakodzera yeganda uye kubvumira nguva yakakwana yekutonhodza panguva yekubatanidza kwakakosha. Pamusoro pezvo, tichifunga nezve polyethylene se crystalline polymer, nzira yekutonhodza tembiricha yakakamurwa, kubva pa70-75°C kusvika 50-55°C, uye pakupedzisira kusvika patembiricha yemukamuri, inobatsira kuderedza kushushikana kwemukati panguva yekutonhodza.

2.3 Kupesvedzera kweCoiling Radius paCable Coiling

Panguva yekukombaira tambo, vagadziri vanotevedzera mitemo yeindasitiri pakusarudza mareel akakodzera ekutumira. Zvisinei, kugadzirisa hurefu hwekutumira tambo hombe dzekunze dzine dhayamita yepamusoro kunokonzera matambudziko pakusarudza mareel akakodzera. Kuti vasvike pakureba kwekutumira, vamwe vagadziri vanoderedza dhayamita dzemareel barrel, zvichikonzera kusakwana kwe radii yekukombama yetambo. Kukombama kwakanyanya kunotungamira mukutama kwezvikamu zvezvombo, zvichikonzera masimba makuru ekuchekerera pa sheath. Muzviitiko zvakakomba, maburi esimbi ane armored strip anogona kubaya sheath yekunamatira, kupinda zvakananga mu sheath uye kukonzera kutsemuka kana kutsemuka pamucheto we strip yesimbi. Panguva yekuiswa kwetambo, kukotama kwe lateral nekudhonza kunoita kuti sheath itsemuke pamwe chete ne clamps idzi, kunyanya kune tambo dziri pedyo ne clamps dzemukati dze reel, zvichiita kuti dzive nyore kutsemuka.

2.4 Mhedzisiro yeNzvimbo yeKuvaka neKuisa panzvimbo

Kuti tambo dzigadzirwe zvakaenzana, zvinokurudzirwa kuderedza kumhanya kwekuiswa kwetambo, kudzivirira kumanikidzwa kwakanyanya kwedivi, kukotama, kudhonza, uye kurovera pamusoro, zvichiita kuti pave nenzvimbo yekuvaka yakanaka. Zviri nani, usati waisa tambo, rega tambo igare pa50-60°C kuti ibudise kushushikana kwemukati kubva mushedhi. Dzivisa kuratidzwa kwetambo kwenguva refu kuzuva rakananga, sezvo tembiricha dzakasiyana-siyana kumativi akasiyana etambo dzinogona kukonzera kushushikana, zvichiwedzera njodzi yekutsemuka kweshedhi panguva yekuiswa kwetambo.

Nguva yekutumira: Zvita-18-2023